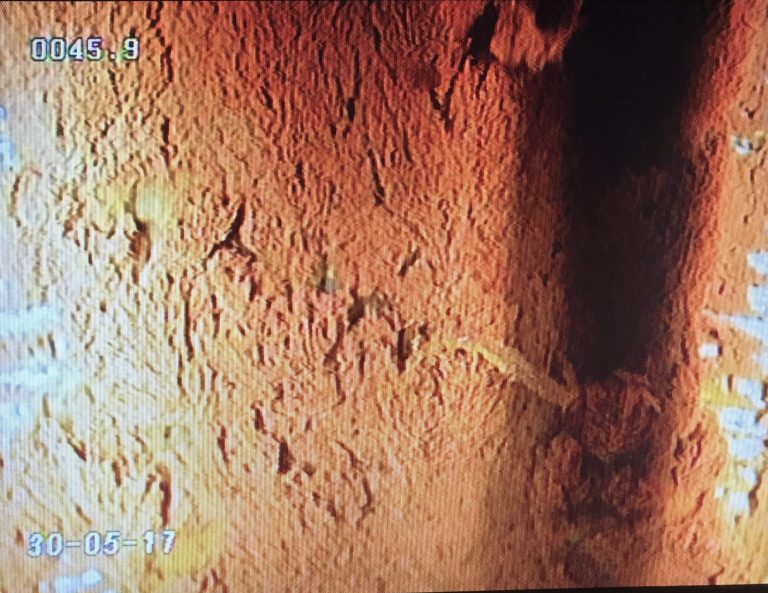

Deposits within the screened area of a water bore have the effect of reducing the open area of the screened section reducing the production yield of the bore and increasing pumping drawdown levels.

Brushing and airlifting is an effective mechanical means of removing fouling material from within the screened apertures that chemical treatments cannot do own their own.

Brushing and airlifting is a one step process where mechanical water bore brushes are specifically sized to remove bacteria from within the screen apertures whilst the airlift is essentially a vacuum that is able to remove the deposits to surface.

Following the water bore mechanical treatment process, chemical treatment typically follows for bacterial infections to prolong the time period before further cleaning is required.

These cleaning processes increase the yield of the bore and reduce electric submersible pump drawdown levels typically to better than the bores original output reducing ongoing water production costs for the bore owner.

To find out more or to discuss any specific needs you have – be it for off the shelf equipment or custom designed equipment, contact AGE Developments.

© 2024 Age Developments | Privacy Policy

Website by Roobix