The most common method used to pressure cement casing for water bore installation is through float shoes or float collars.

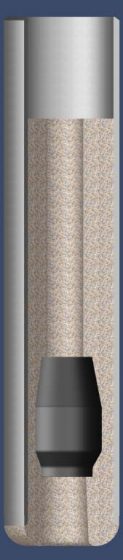

They comprise a length of pipe connected to the bore casing string, with a non-return valve encased by a drillable material. This encasing material is a rubber-filled cement composite that we have developed in-house to allow for a fast, efficient drill out whilst being able to support tremendous differential pressures. For classical bore construction design, they provide an effective method of floating the bore casing to depth minimising load on the drill mast during casing installation.

They are designed to be run in on the casing string (on the bottom for shoes and in-line for collars) to facilitate pressure cementing from the bottom back to surface. The non-return valve prevents back flow of grout into the casing once pumped through the valve. When the grout is set, they can be easily drilled through to install telescoped bore screens or further casing.

AGE Float Shoes are available in two different types; Standard and Stab-in. A Stab-in arrangement allows the drill string to be sealed into the Float Shoe, ensuring that all cement flow is directed through the shoe and into the annulus. This helps to ensure that a deposit of cement is not left on top of the shoe, which can slow down subsequent drill-out.

We have specially designed these products for water bore applications and they are available to suit all water bore casing sizes and materials.

Standard sizes and types available in stainless steel & mild steel materials with either single valve or dual valve configurations. Special sizes are available on request with either threaded or welded connection.

To find out more or to discuss any specific needs you have – be it for off the shelf equipment or custom designed equipment, contact AGE Developments.

© 2024 Age Developments | Privacy Policy

Website by Roobix