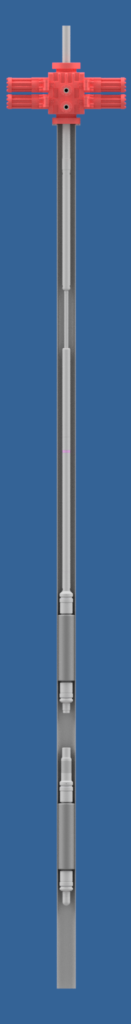

AGE Developments have a range of casing integrity test packer equipment to suit standard casing sizes complete with a four stage valve system that enables:

• Stage 1 – Through string inflatable packer element inflation;

• Stage 2 – Annular circulation above packer for testing casing above packer against BOP annular;

• Stage 3 – Complete well shut-in to allow casing above packer to be tested via tree well kill lines or monitored for pressure drop;

• Stage 4 – Injection below packer against retrievable bridge plug (in single packer configuration) or a specific test zone via straddle packer arrangement.

The test equipment and stage valve has multi-cycle functionality meaning multiple tests can be carried out in a leak hunting program to accurately define the top and bottom depth of the leak zone without the need to trip equipment from the well.

Combined with AGE High Differential Pressure Packer Elements, high test pressures are easily achieved even in wax filled casing. 9 5/8” casing High Differential Packer Elements have been tested in this environment and proven to support 176kips differential load repeatedly.

Casing integrity test equipment is suitable for the following casing sizes 5 1/2″, 7″, 9 5/8″ and 13 3/8″ with other sizes available upon request.

To find out more or to discuss any specific needs you have – be it for off the shelf equipment or custom designed equipment, contact AGE Developments.

© 2024 Age Developments | Privacy Policy

Website by Roobix